Buoys Bobbin' in the Bay

Opening Monologue

Welcome to the 10th installment of the Captain's Log! Originally, I was going to write about hoarding this week, but that hasn't really panned out in a way that I think makes sense yet... Instead of an unhinged update, you'll get an incredibly straightforward account of one of the busiest weeks of my life...

This has been the week from hell. I'm not sure I'd say it was quite bad enough to be Type III fun, but I wouldn't say it was Type II fun either. I managed a boat ride out of it after all. How bad could it be?

Here's the quick summary. I had 8 days worth of work to do before Wednesday all on top of several urgent consulting requests I got on Monday that really threw a wrench in things. All of it incredibly high stakes, high priority and high stress. But here I am. I got 12 hours of sleep last night, and shockingly have closure on everything from last week. Aside from the superfund site that is my desk, I can walk into the shop on Monday and it'll be a completely new week.

This Week

XB-X Top Collar

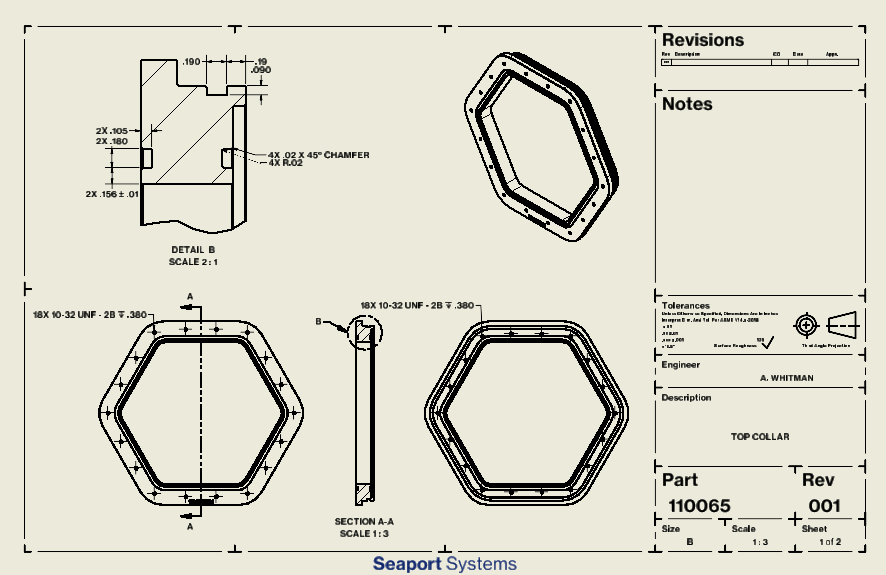

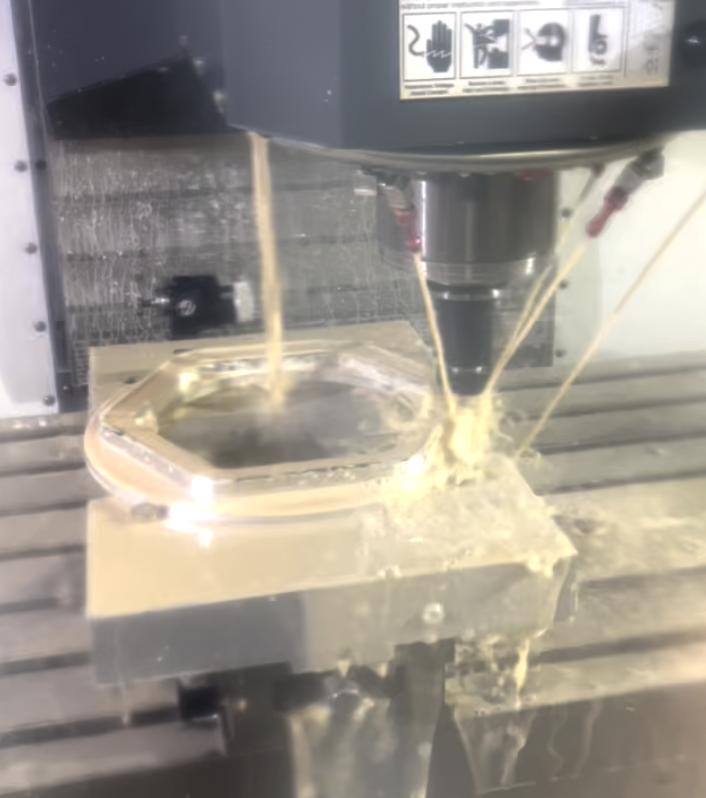

After tending to the most catastrophic 3D print failure I've ever seen, I hopped into the machine shop to get the new Top Collar machined. I detailed the changes in last week's update, but basically the o-ring grooves match now, and I added more bolts to the bolt pattern. Machining was shockingly uneventful. Setup, Op1 and OP2 took less than an hour and a half. The real takeaway, besides a clean part ready for Thursday's deployment, is being far more comfortable with CNC programming and operating the VF-5.

New 110065/001 - TOP COLLAR, in the flesh!

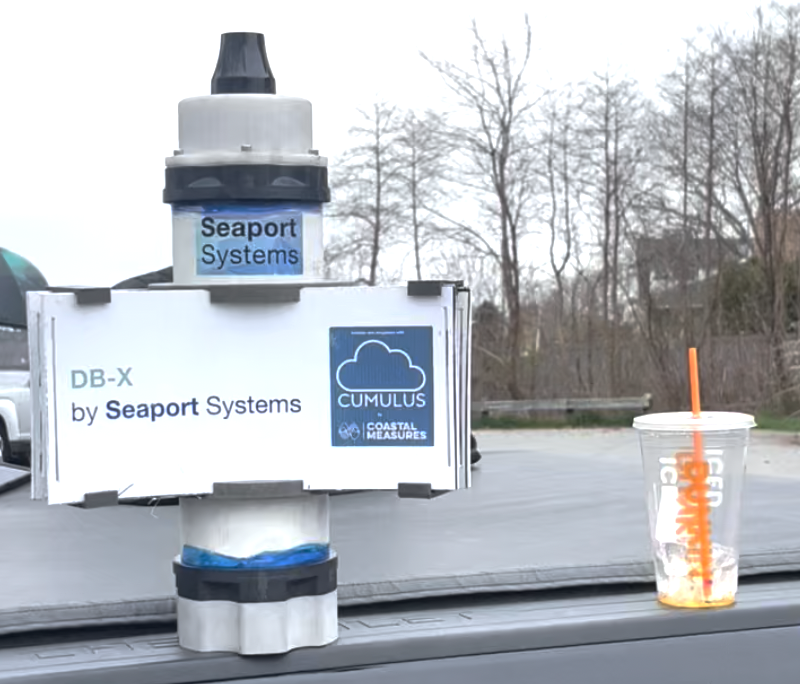

DB-X Final Assembly

Tuesday marks the first time the DB-X has been permanently assembled, and that went exactly to plan.

The body of the DB-X is made of a PVC tube hull, several 3D printed inserts that slide into the tube, and two flanges at either end of the tube. The flanges are milled from PVC, and are solvent bonded to the tube itself - this is the fun smelling purple/clear cement you'd find at Home Depot for doing home plumbing. The solvent bond is great because it chemically reacts with the PVC on both parts so they melt into each other and form one solid, sealed piece. The end caps then permanently capture the 3D printed inserts for the battery and electronics, which themselves are field replaceable.

A few new inserts printed over the weekend made it easier to insert and remove the battery and route the cables for the electronics.

Demos and Deployments

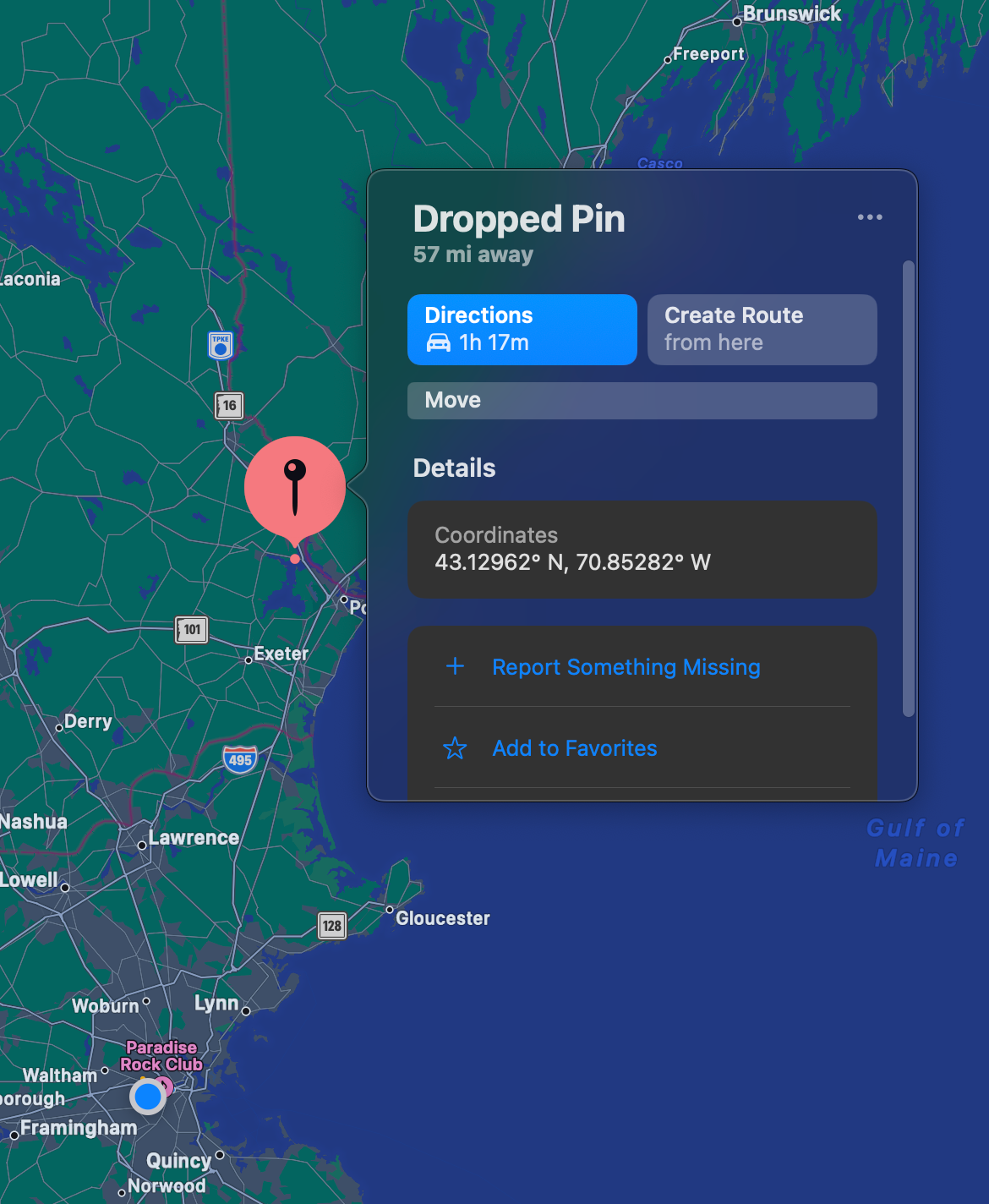

Tuesday morning marked the start of a two day testing road trip. I was up around 5:30am, made it to the office to by 6am and was on my way out of town, past Kowloon by 7:00am.

First stop was Little Bay, New Hampshire. Laura Brown, our host from Fox Point Oysters has been over the moon about the opportunity to monitor her farm and democratize citizen science. She's provided a lot of boots on the ground type feedback that's already started to make its way on to the buoys and the long term roadmap!

At Fox Point, I was demoing the DB-X with Laura, and the Coastal Measures team - Josh and Neil, as well as Erik from Heavy Edition.

The DB-X was originally Coastal Measures' creation, but they handed it off to Seaport Systems several months ago. We met because we went through the same incubator program at the Gulf of Maine Research Institute, although in different cohorts. They have extensive experience in data storage, analysis and machine learning and wanted to get the hardware side of the ocean data problem off their plate. I've focused Seaport Systems on the hardware side of the problem since the beginning, so naturally it's been a really fruitful partnership so far and we're excited to start shipping product soon!

Erik, who started Heavy Edition, a content studio and video production company in Maine, also comes to us via networking events at GMRI. I've met Erik a handful of times, but he's been working more directly with Coastal Measures to document their journey from passion project and pitch competition to what it's become now!

On Tuesday, we all came together to shoot some footage on Laura's farm and of the DB-X demo. Mind you, this is the first live demo, ever. I'd only ever dropped it into the shipping terminal at the Boston Harbor. Overall, I was pretty on edge and nervous. I handed the buoy off to Josh who waded out into the water then stuck my head into the computer to watch telemetry come back. It was reporting perfectly, everything was great, then I turn around to see Josh shot-putting the DB-X 15 feet in the air out into the bay. The look on my face must've been something, but I'm glad Erik got footage of the buoy in the air, not the vein in my forehead throbbing vigorously.

I got a couple of awesome Instagram stories out of the demo. Hopefully Erik and I can connect to get more polished footage for the website, because my poor cracked out iPhone is carrying this company's marketing efforts far more than it has any business doing.

Wednesday afternoon I had some time to catch my breath a bit before heading out to Ferda Farms Thursday morning. Max and I wrote a grant last year to the USDA to implement monitoring on his oyster farm in Brunswick, Maine. His deployment will eventually consist of 3 XB-X buoys and we're going to look at modeling oyster growth against environmental conditions. We were supposed to get data through most of last season, but I wasn't able to get the prototypes operational in time. Max and the USDA have been patient and graceful enough to extend the grant through this growing season and we're closer than ever.

After how well the DB-X demo went in New Hampshire, I wanted to push my luck and see if we could go 2 for 2. Max and I took the skiff up river maybe half a mile, tossed out the DB-X and headed back to Ferda's work float. While we waited, I spent some time working on the XB-X.

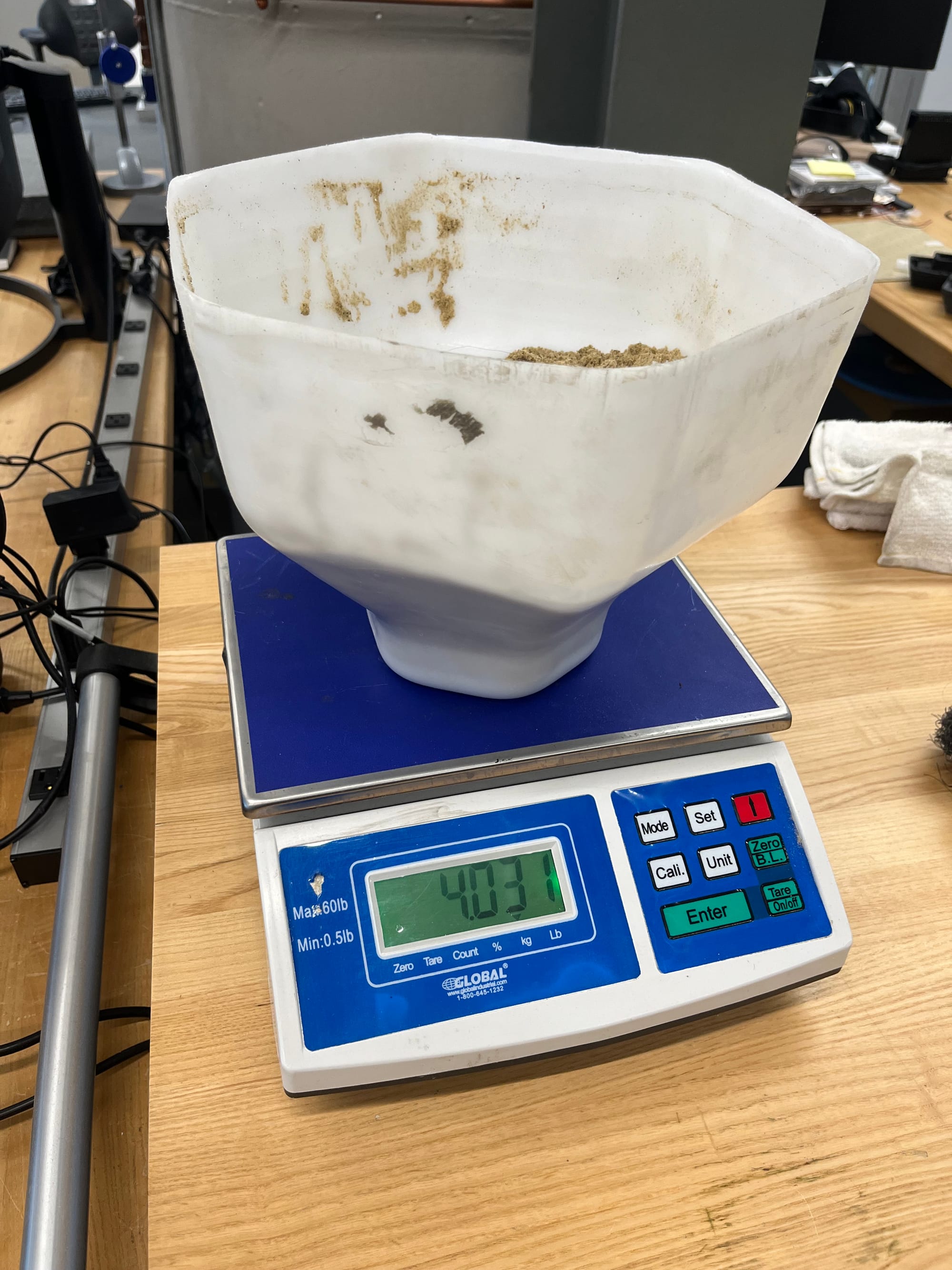

This week, I was testing everything except the electronics. This is the first time the hull, and electronics housing have been completely sealed up. I've spent a good amount of time calculating the ballast needed in the XB-X. That being said, it doesn't matter what happens on paper, reality trumps all, so I brought out a bag of sand that I'd simulate the ballast weight with, by pouring it into the hull and checking to see how it sits and behaves in the water. Archimedes says I want ~7 pounds of ballast at the bottom, which seems pretty spot on. I weighed out 7.75 pounds after testing, but the buoy was sitting a little lower than I needed, so I'm thinking this Archimedes guy was on to something.

The last time I bought sand at Home Depot, things got out of hand very quickly...

After wrapping up at Ferda Farms, I started the journey south back to Boston, and I've been borderline braindead ever since, go figure.

Next Week

DB-X Software and Calibration

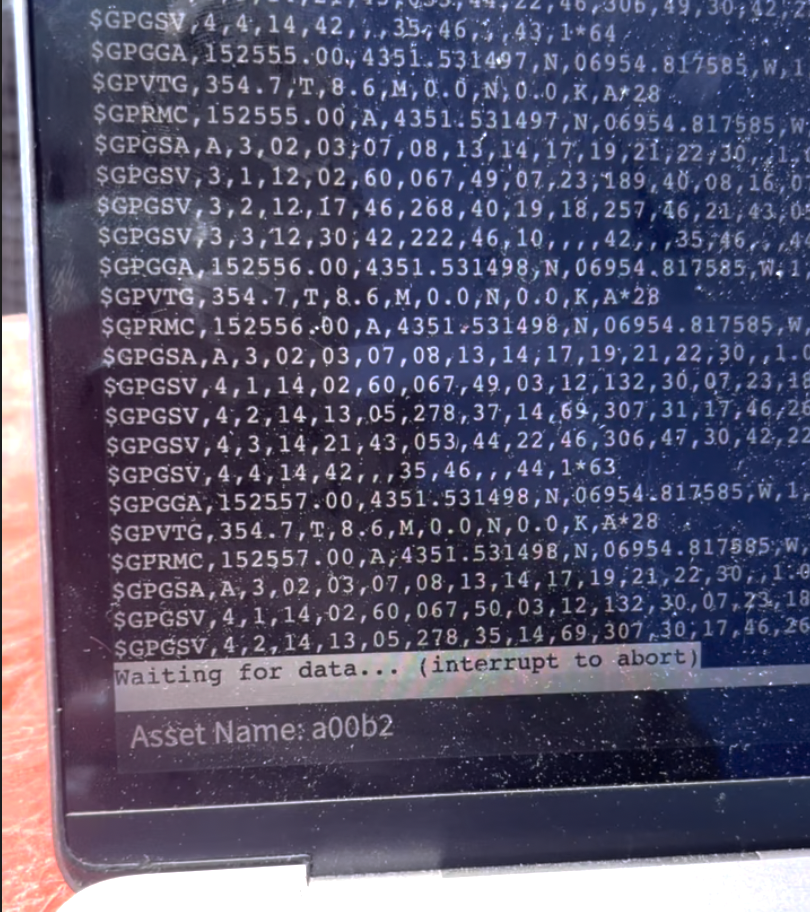

Testing of the DB-X so far has been SSHing into it, and watching the log file fill up with all of the NMEA0183 sentences from the GPS. Obviously that's not a fully baked solution, so I'm going to work to get it tied into Coastal Measure's Cumulus platform with MQTT. On Cumulus, end users can easily administer their buoys and access all the data they've collected over time! I'll start with getting the DB-X integrated, but the hope is that the XB-X is interfaced primarily here as well!

XB-X Latches

I must've done a dozen rounds of latch prototyping before realizing I made those models and tested the latches without the polycarbonate cover in between the hull and the latch. It changes the geometry entirely and I'm back at the drawing board... Stupid stupid stupid.

XB-X Electronics Housing Mold

Hoping to re-machine the electronics housing mold this week. You might remember from the last update that the previous mold was made of a foam covered in epoxy that glued itself to the resulting vacuum formed part... This time I'll make it out of the tried and true MDF that's been used everywhere else.

XB-X Ballast

After some math and testing this week, I know exactly how much the ballast needs to weigh, and where it needs to be placed, but a pile of sand isn't viable in a production product for a variety of reasons. Sand isn't dense enough, it takes up too much volume in the hull. It’s coarse and rough and irritating… and it gets everywhere.. It'll shift around with the waves, potentially leading to a situation where the buoy is no longer stable. I also want to use the ballast weight as a firm place for the mooring to attach to. Sand is not firm.

So, more CAD, machining, and testing on the agenda...

Wins

Testing

See the above exposition.

Dunkin' Donuts

You're a true New Englander ripping iced coffee in the freezing cold - Laura Brown, Fox Point Oysters

Obviously the caffeine is key to any successful op, but this wouldn't be a truly genuine account if I didn't also acknowledge the 3+3 deal that kept me fed along the road trip. A medium iced coffee and a sausage egg and cheese for $6! We're living in mad times! While I've been radicalized by my grocery bill, Dunkin manages to keep it real.

It's not part of the combo, but you've gotta go the extra mile and add the hash browns to the sandwich. Can't forget to ask for a couple of ketchup packets either. I've been exercising a lot and generally speaking eating better lately, but I will forever be a fat kid at heart and I'd much rather die fat and happy with this monstrosity than spend $17 for an, eel grass, yoga sweat pressed juice.

Minnesota Twins Summer Sausage

7 in a row. This thing is heinous, but I'm glad it works.

One update about sausage is curious, but two is uncanny...

Losses

Sleep

Not sure what the sleep deficit is this week, but I've been tired at 6pm and sleeping comfortably through 9am since I got back. I don't miss college, I don't miss all-nighters. I like my sleep.

Project Management

Sometimes, all hell breaks loose... Any semblance of schedule, planning and management went out the window in the wee hours of Tuesday morning. It all worked out in the end, but we've really gotta ground ourselves and put together a more comprehensive outlook for the next few weeks.

Closing Monologue

This has been the 10th blog! I'm not big into anniversaries or birthdays or that sort of thing, but I feel like there's a a lot worth celebrating here! I've started and shored up a new habit of blogging. Successful tests and demos that appear to be leading in great directions. Spring time. What's not worthy of celebration?!

Ashley and I are headed to the Red Sox/Cubs game, so that's all I've got.

Thank you as always to those taking time out of your busy days to acknowledge my writing, it means a lot! Cheers to another 10 blogs!